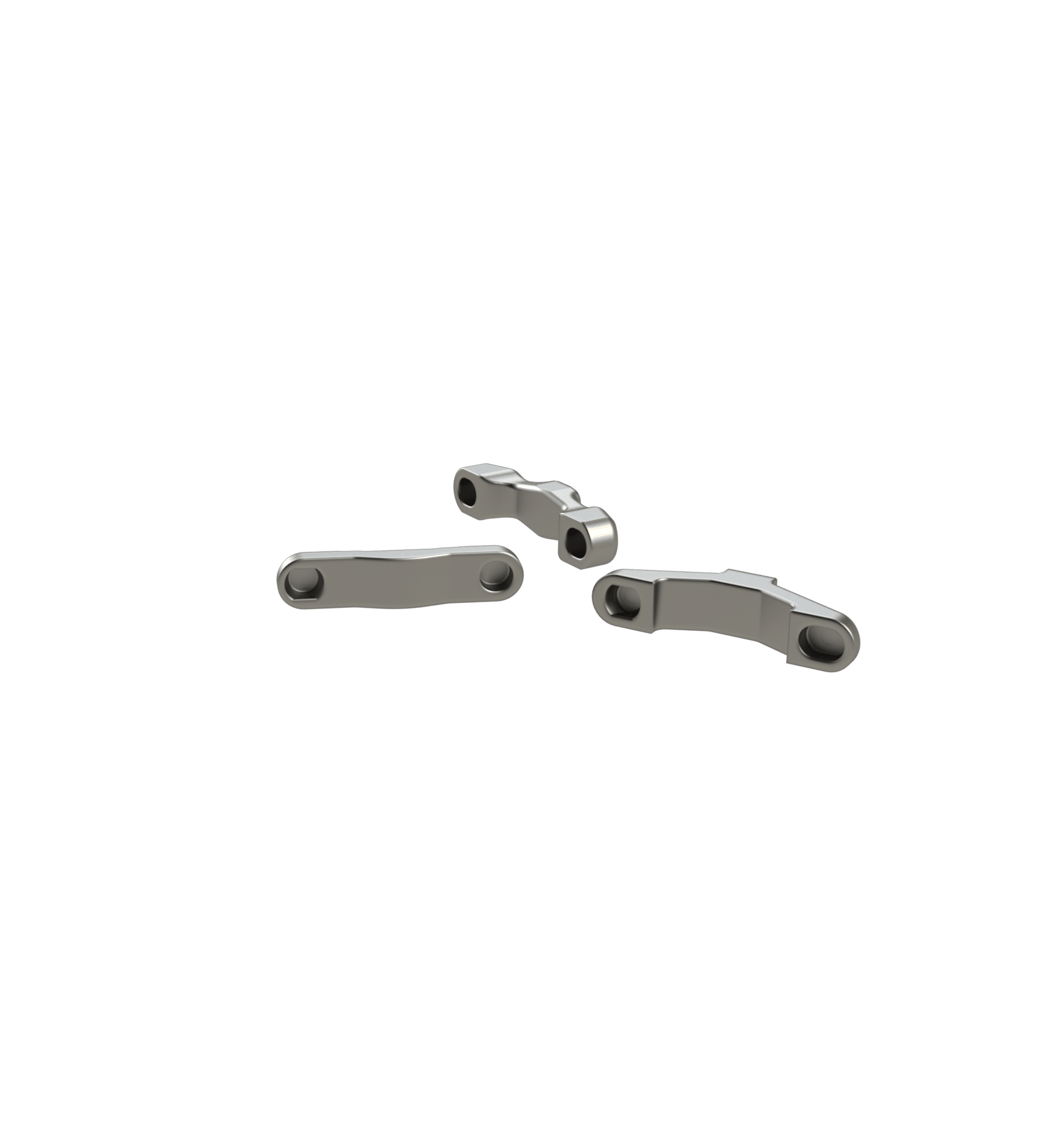

Engine Crossheads

NETFORM has developed a unique cold forming process for diesel engine crossheads that reduces system costs. The crossheads are cold formed and ready to use. No machining is necessary, with all surfaces being as–formed. Crossheads are also heat–treated to provide the required wear characteristics.