Pinion Carrier

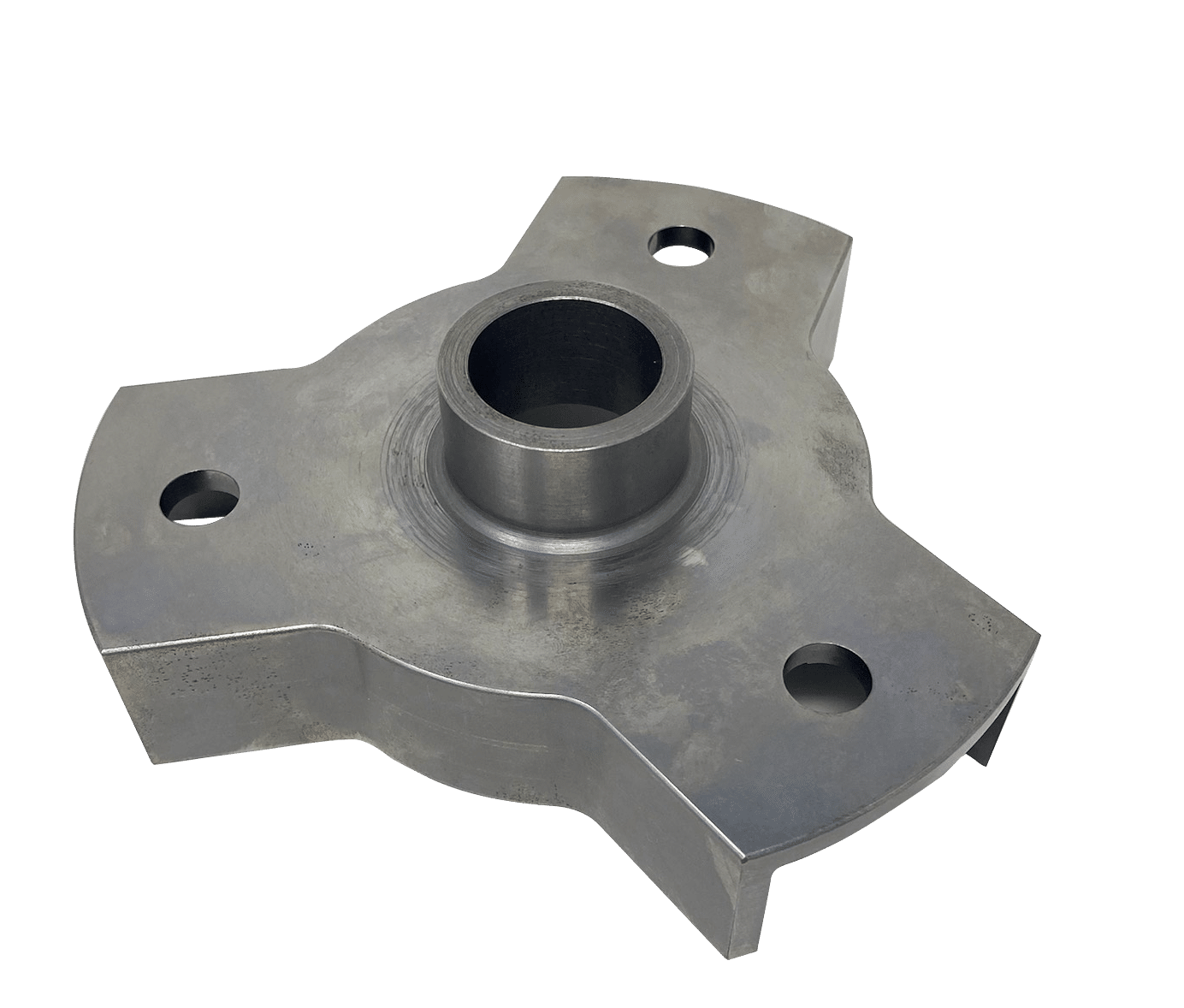

NETFORM has manufactured millions of cold-formed carriers for powertrain applications over the last twenty years. These carriers, supplied ready to assemble, incorporate many as-formed features.

NETFORM has manufactured millions of cold-formed carriers for powertrain applications over the last twenty years. These carriers, supplied ready to assemble, incorporate many as-formed features.

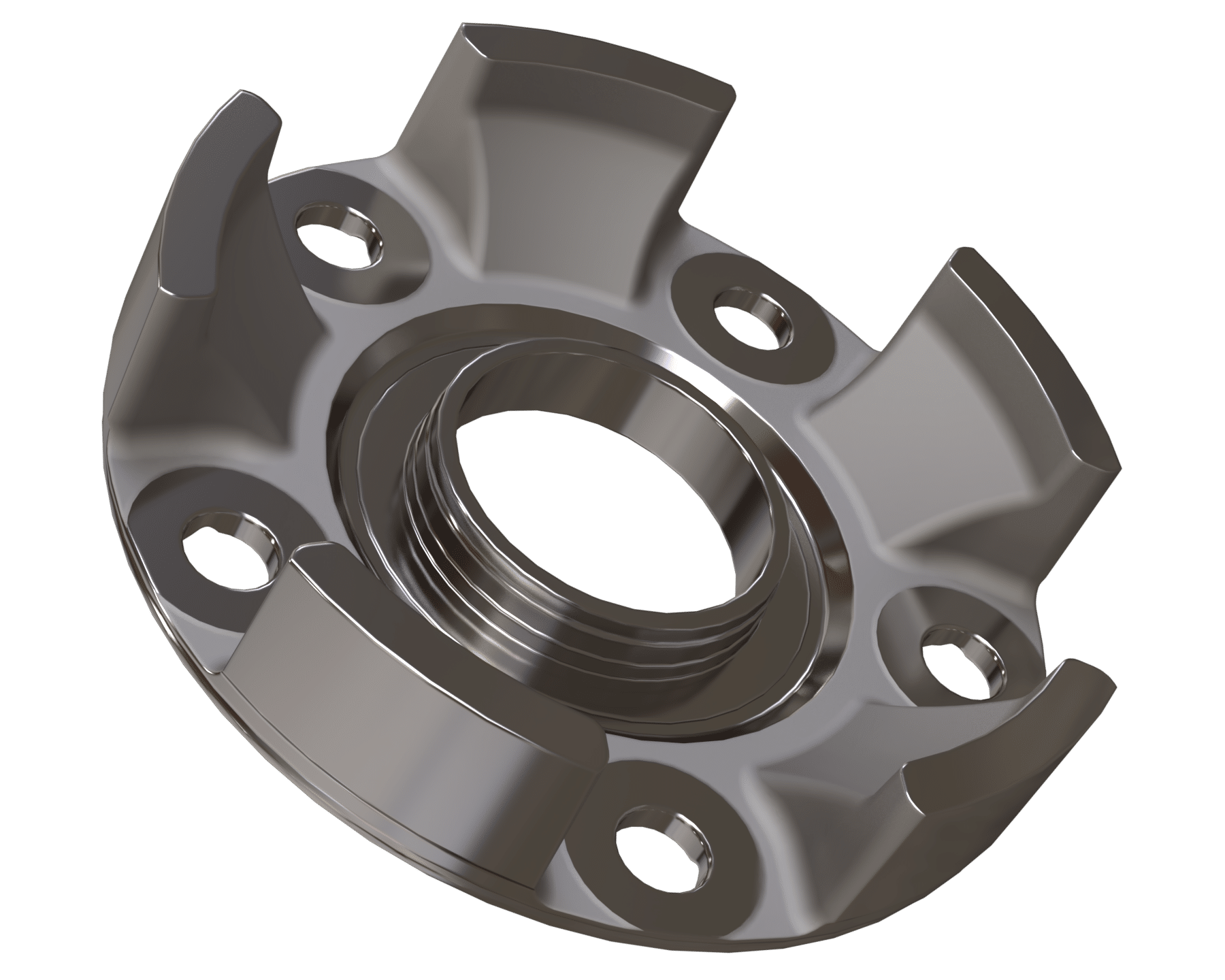

NETFORM also manufactures fully-machined powertrain carriers. Processes include broaching, milling, drilling, deburring set up in dedicated machining cells.

The evolving nature of the powertrain industry is driving change at the component level.

Products are required that are larger, stronger and lighter than current carriers manufactured.

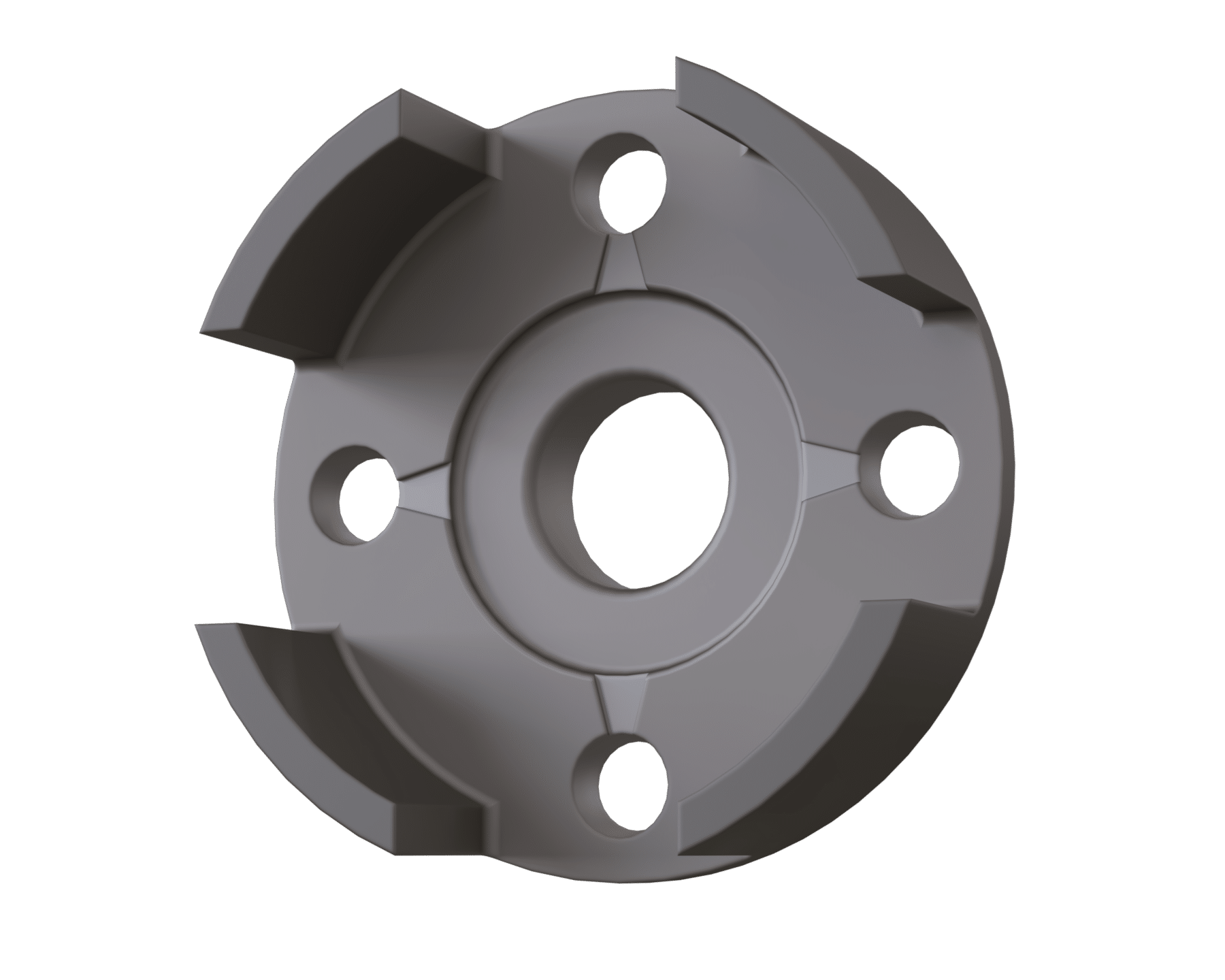

The “tripod” carrier shown allows carriers of up to 8″ diameter to be formed.

The carrier with stiffening webs is for applications when the stiffness requirements of the part require additional support.

Cold forming (also called cold forging or coining is a process where material is transformed into new shapes at room temperate in high-tonnage presses.

The very nature of the cold forming process requires material with highly formable properties. These properties do not lend themselves easily to machining. Chip management is particularly challenging due to the machined material not wanting to break during machining.

In addition, the nature of cold forming requires that excess material over the finished components is minimized. This result in very small depths of cut during machining.

The NETFORM approach can help you reduce emissions, improve performance and drive profitability.