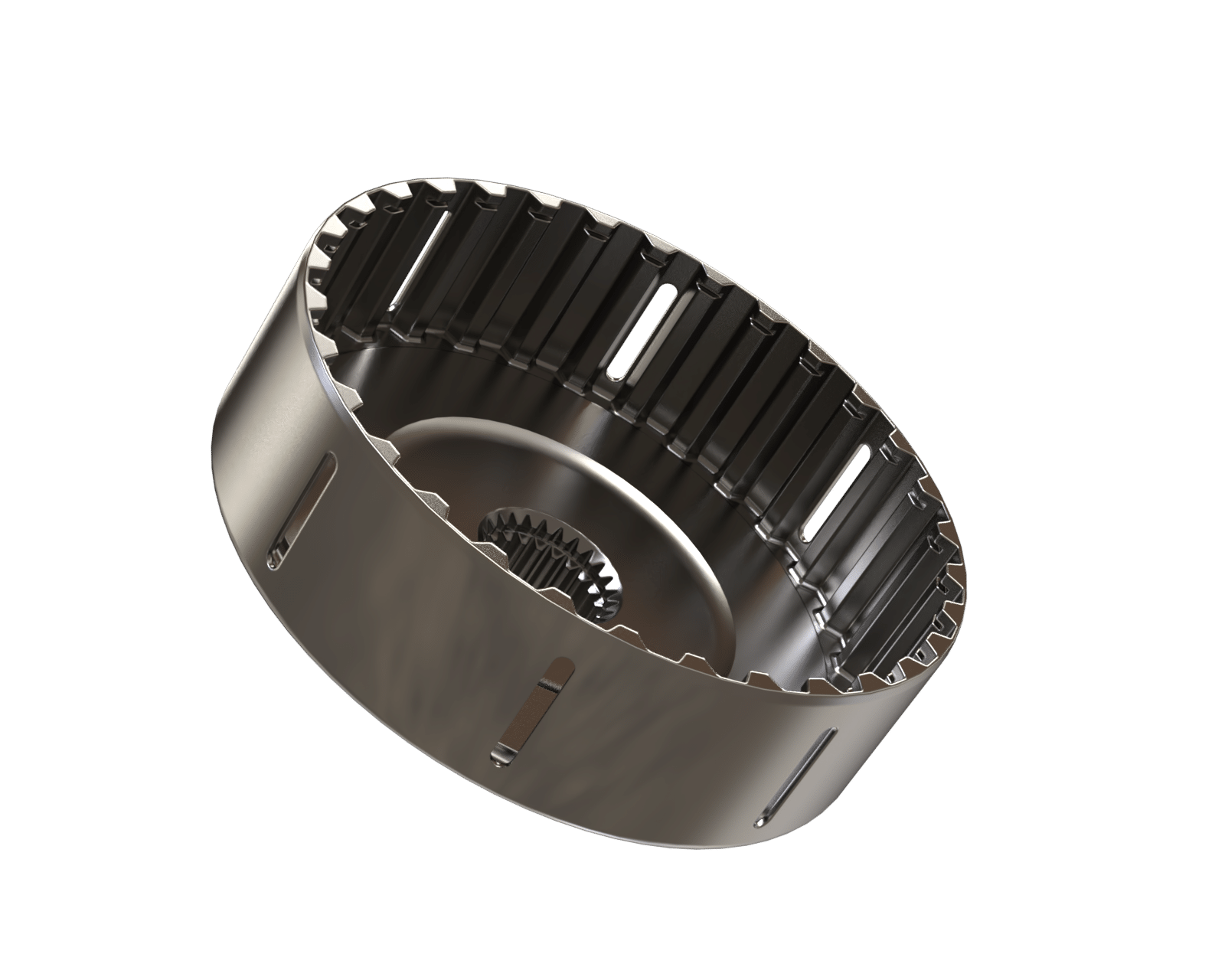

Clutch Drums

NETFORM has developed expertise in the area of flowformed drums for use in powertrain applications.

Key product differentiation in this area is through the opportunity to use unique cold forming technology for the production of the preform. This technology can eliminate the need for both heat treatment and laser welding operations. It also allows for part consolidation resulting in the reduction of program capital, tooling, supply-base activities and warranty issues.

Flowformed drums are finished machined in dedicated, automated machining cells.