Traditional Tube Manufacturing Processes

Traditionally, tubes are manufactured on tube mills. Tubes – constant diameter, constant wall thickness – are made in semi-continuous processes, either seamless or welded. Tubes are then cut to length (typically 20’ or so), and then further processed as required.

There are limitations with the standard tube mill process. These include:

- High diameter-to-thickness tubes are difficult to manufacture

- Tubes are limited to single thickness/constant diameters.

- OD variation as part of the manufacturing process is not possible

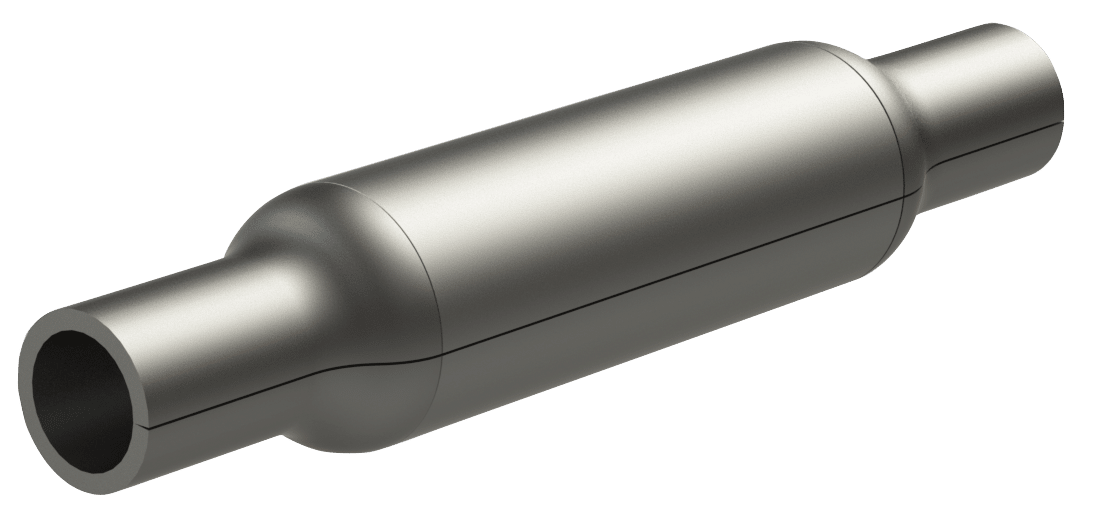

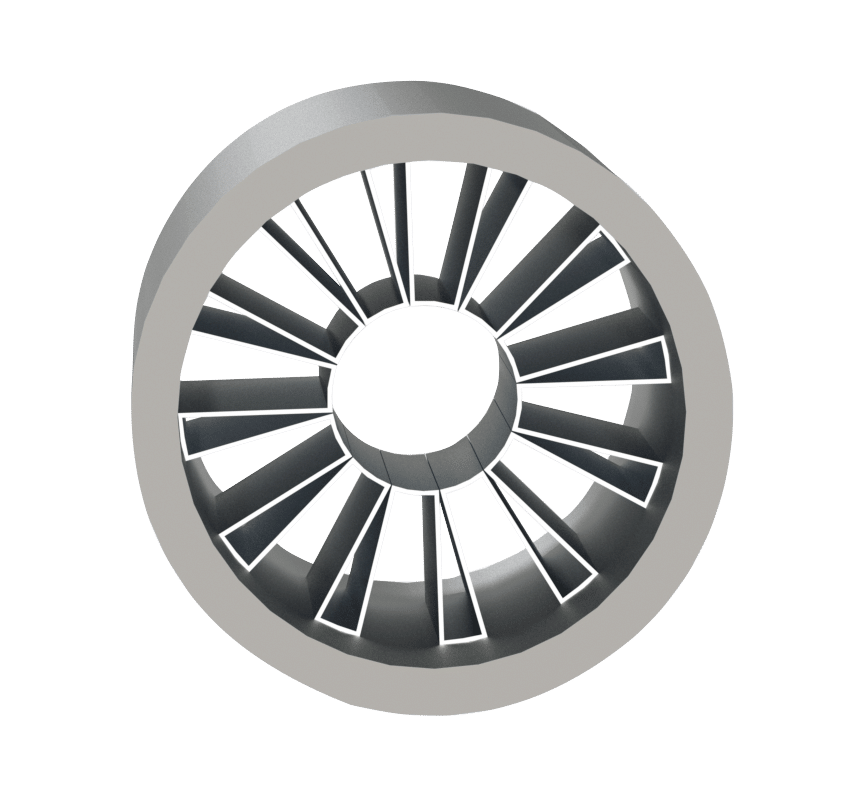

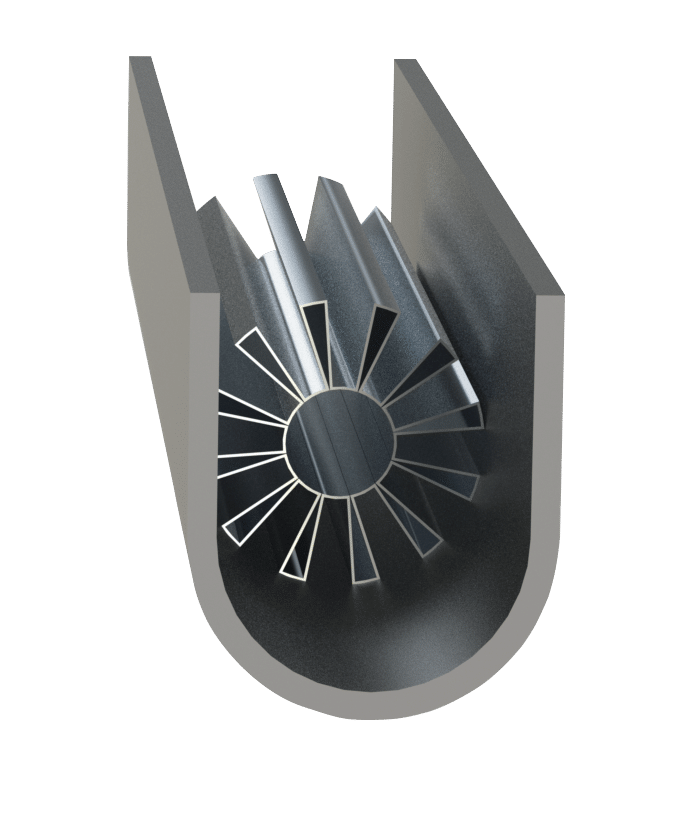

Netform has developed an approach to tube manufacturing that has two major differences to the tube mill process:

- The forming of the tube is carried out using the principles of transfer die stamping

- The tube is seam welded after the press operation.

This approach allows for a completely different approach to tubular product manufacture.