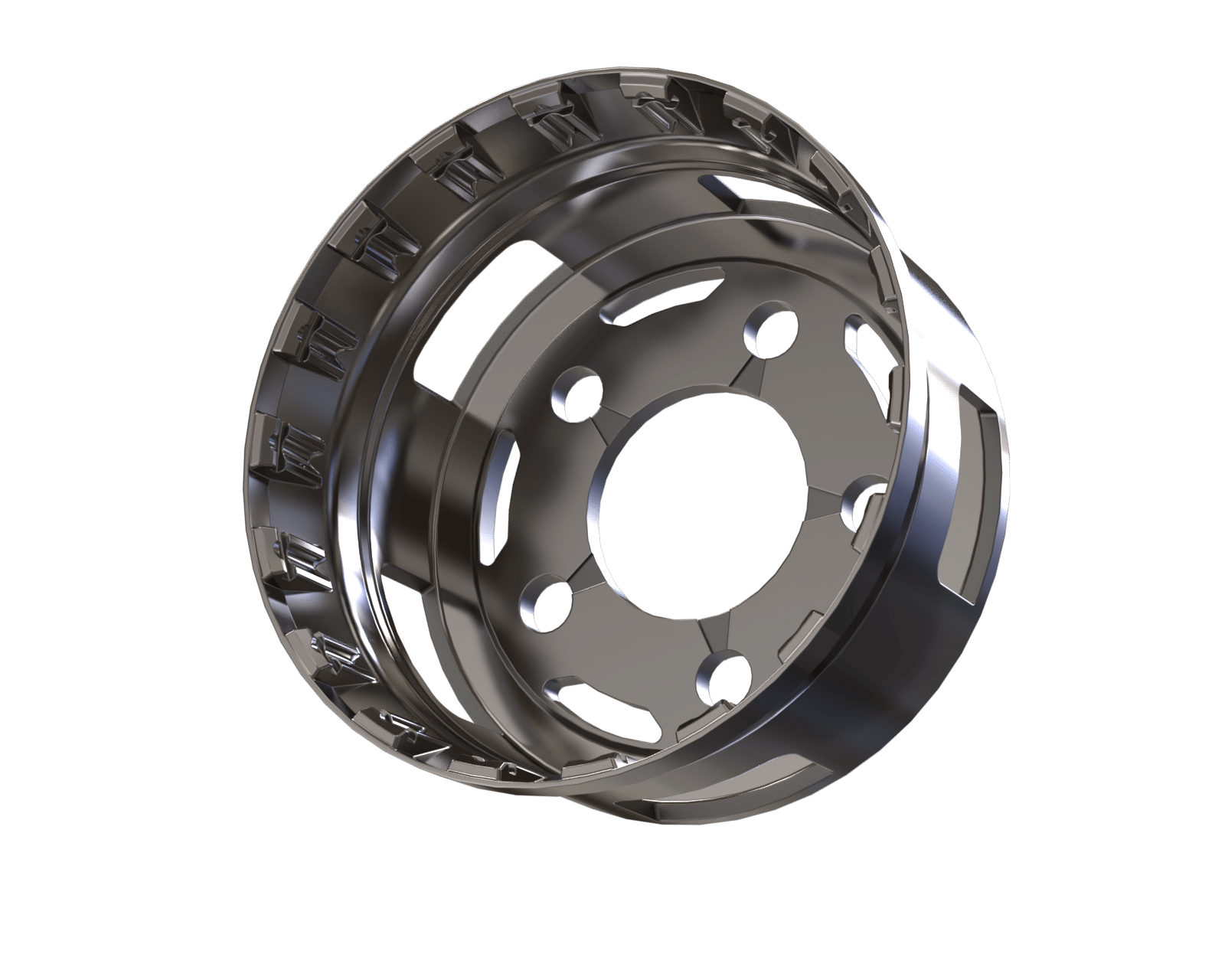

Carrier Shells

NETFORM has expertise in the area of flowformed, fully-machined carrier shells. Formed out of 1035 steel, these products are supplied to the customer ready for assembly.

NETFORM has expertise in the area of flowformed, fully-machined carrier shells. Formed out of 1035 steel, these products are supplied to the customer ready for assembly.

Flowforming is a cold rotary forming process where a rotating metal preform is formed over a tool by (typically) three rollers.

The rollers deform the preform, forcing it against the tool (also known as a mandrel), axially lengthening and radially thinning the material.

The material will take on the reverse profile of the mandrel, allowing the forming of features such as splines and piston seal surfaces.

The very nature of the cold forming process requires material with highly formable properties. These properties do not lend themselves easily to machining. Chip management is particularly challenging due to the machined material not wanting to break during machining.

In addition, the nature of cold forming requires that excess material over the finished components is minimized. This result in very small depths of cut during machining.

An OEM was developing a nine-speed transmission and had a complex assembly for transmitting torque in the planetary carrier area.

The NETFORM approach can help you reduce emissions, improve performance and drive profitability.